This article delves into the crucial role of inventory management during crises, offering insights and strategies to weather the storm and emerge stronger on the other side.

The resilient backbone: inventory in crisis

When crises strike, the significance of a well-organized inventory system becomes abundantly clear. A robust inventory management strategy serves as the backbone of resilience, allowing businesses to respond swiftly to challenges while maintaining essential operations. Well-prepared businesses establish crisis response plans that leverage inventory data to prioritize critical products, assess alternative suppliers, and adjust distribution channels.

Demand fluctuations and agility

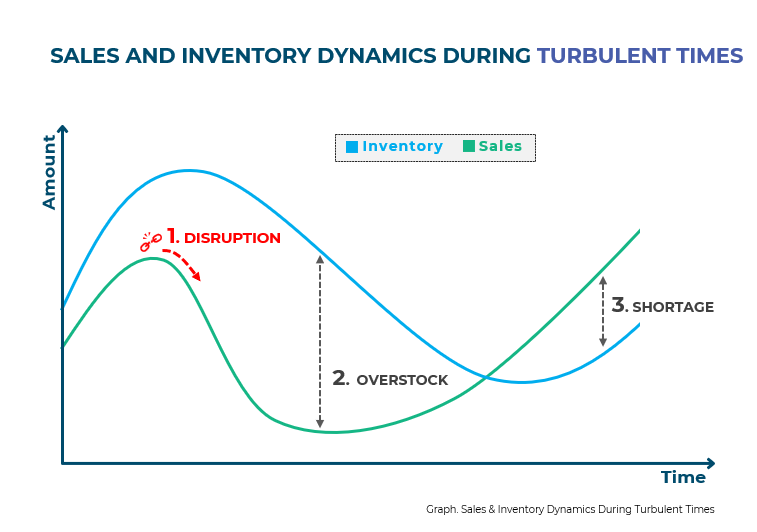

Crisis scenarios often trigger rapid shifts in consumer demand. The ability to recalibrate inventory levels in response to changing customer preferences and emerging trends is pivotal. Agile inventory management empowers businesses to anticipate these fluctuations, adapt supply chains, and allocate resources strategically. Data-driven demand forecasting tools and predictive analytics become invaluable allies in optimizing inventory in alignment with dynamic market demands.

Supplier relationships and risk mitigation

Crisis events can disrupt supplier networks, leading to delays, shortages, and production standstills. Effective inventory management hinges on cultivating strong supplier relationships and diversifying sourcing options. Businesses that maintain transparent communication, collaborate closely with suppliers, and implement risk mitigation strategies ensure a steady flow of critical inventory even in the face of unforeseen disruptions.

Lean principles and efficiency gains

Lean inventory principles take center stage during crises, emphasizing the elimination of waste, streamlined processes, and efficient resource allocation. Implementing lean methodologies allows businesses to reduce excess inventory, optimize storage space, and enhance cost control. The crisis becomes an opportunity to reevaluate inventory practices, identify bottlenecks, and institute lean strategies that deliver lasting efficiency gains.

Resilience redefined: emerging stronger

As the dust settles after a crisis, businesses that have embraced effective inventory management find themselves poised for recovery and growth. The lessons learned in navigating disruptions pave the way for enhanced crisis preparedness, refined supply chain strategies, and a newfound understanding of the pivotal role inventory optimization plays in ensuring business continuity.

In a world where uncertainty is the only certainty, the role of inventory management as a crisis buffer cannot be overstated. By embracing proactive strategies, leveraging technology, and fostering strong partnerships, businesses can emerge from crises with minimal disruption, fortified supply chains, and renewed resilience. As you navigate the tumultuous waters of business, heed the call to empower your inventory management practices – the compass that guides you through the storm and toward a horizon of enduring success and operational continuity.

If you would like to learn more about this subject or want a more in-depth analysis on one of the topics discussed above, our specialists at Moore are available to assist you.